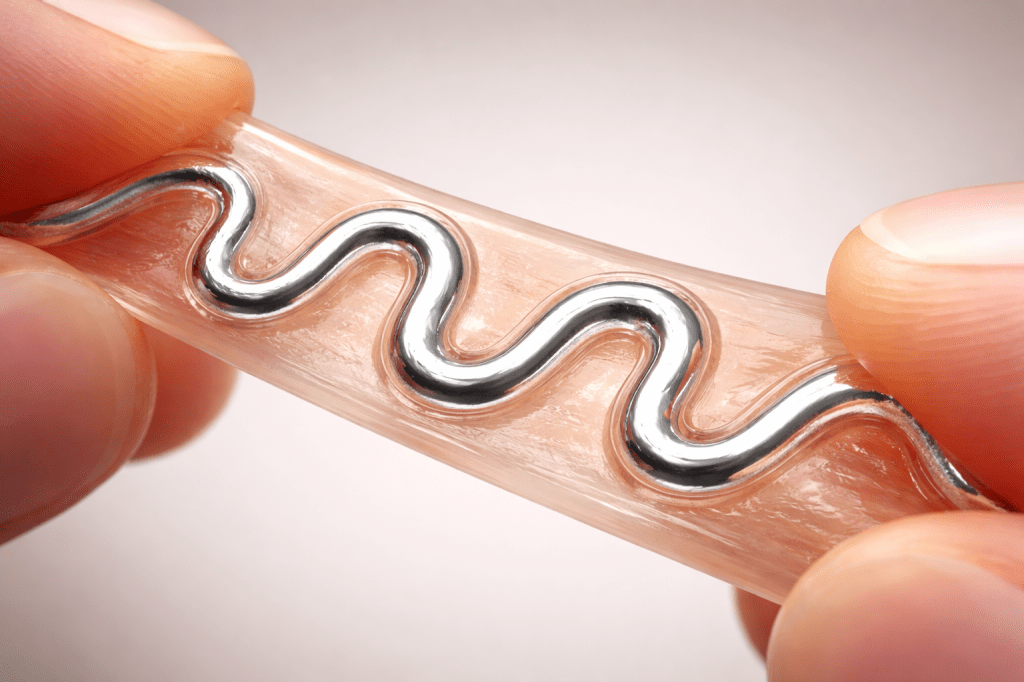

Dear Cherubs, meet a new kind of wire that laughs at twisting, folding and stretching — it keeps the juice flowing even when you treat it like a party streamer. Scientists in China mixed elastic polymers with liquid metals such as gallium–indium to make a metal-polymer conductor (MPC) that stays conductive under dramatic deformation, and yes, that’s actually useful.

The trick is not magic. It’s liquid metal particles embedded in a rubbery host so the metal can rearrange as the polymer flexes. According to the iScience paper reporting the work, the printed MPCs sustain astonishing stretch (reported up to 500%) while keeping conductivity high; the authors measured roughly 2,316 S/cm at 500% strain and tiny resistance drift after thousands of cycles. That’s the sort of durability you want in wearable sensors or soft robots, not a wire that gives up after one yoga pose.

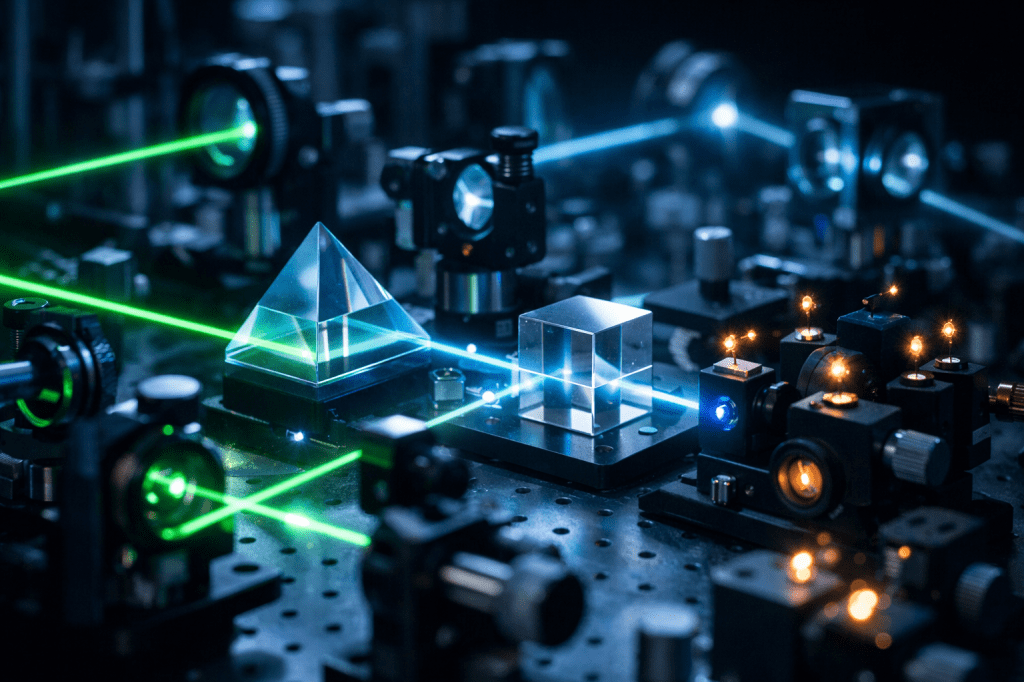

HOW IT WORKS

Liquid metals such as eutectic gallium-indium behave like metals electrically but like fluids mechanically. That duality means they can deform without cracking, but their surface tension and oxide skin make patterning tricky. The iScience team got around that by patterning liquid-metal particles and embedding them into an elastomeric polymer, producing a surface-embedded metal network that resists leakage and fatigue. Reviews of liquid-metal electronics note similar approaches are central to e-skins, stretchable interconnects and self-healing contacts.

Two practical benefits stood out: repeatability and manufacturing friendliness. The researchers reported very small resistance changes after repeated stretching (reported ΔR/R <3% after 10,000 cycles), and the technique can be adapted for screen-printing and scalable patterning. In plain English: you could print these conductors like ink and wrap them around a limb or stitch them into clothing. The iScience work emphasized biocompatibility too, which nudges this tech from novelty to potential medical sensors or implantables (reported in the paper and discussed in subsequent reviews).

WHERE THIS MIGHT GO

Expect soft robotics that won’t be stymied by a bend, wearable patches that track health without peeling off, and prosthetic skins that sense pressure without shorting out. That said, liquid-metal alloys bring their own housekeeping needs — oxidation, potential alloying with other metals, and encapsulation for long-term implants — so it’s not quite “drop it in and you’re cyborg.” Recent reviews and follow-on studies highlight progress on containment, patterning and laser-sintering techniques that reduce leakage and improve resolution.

If you want to dive deeper, the original study and several reviews lay out the performance numbers, manufacturing approaches and remaining hurdles. For a more general explainer and related coverage, check thisclaimer.com for perspective and links to demonstrations and videos.

Sources list — plain text (one per line):

iScience (Tang et al., Printable Metal-Polymer Conductors for Highly Stretchable Bio-Devices) — https://pmc.ncbi.nlm.nih.gov/articles/PMC6146547/

ScienceDaily (news summary of the iScience work) — https://www.sciencedaily.com/releases/2018/06/180614213840.htm

Physics World (news coverage of printed metal-polymer conductors) — https://physicsworld.com/a/printed-metal-polymer-conductors-make-stretchy-biodevices/

Nature Communications / Nature partner reviews on liquid-metal stretchable electronics — https://www.nature.com/articles/s41528-024-00298-z

Advanced Materials (on biphasic gallium-indium stretchable circuits) — https://onlinelibrary.wiley.com/doi/10.1002/adma.201706157

PubMed entry for the iScience article — https://pubmed.ncbi.nlm.nih.gov/30240749/

PMC review on fiber-based soft electronics enabled by liquid metal — https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10175636/

ResearchGate (supplementary material and PDFs for the iScience paper) — https://www.researchgate.net/publication/325774931_Printable_Metal-Polymer_Conductors_for_Highly_Stretchable_Bio-Devices

Recent laser micromachining PDF discussing patterning of liquid metal for stretchable electronics — https://smr.unl.edu/papers/Palvanova_et_al-2025-AMT.pdf

thisclaimer.com — https://thisclaimer.com

Leave a comment